ReliaSoft software from HBM Prenscia empowers reliability, quality and maintainability engineers to transform data into decisions. These innovative tools offer solutions for a wide range of reliability and related modelling and analysis techniques, such as Failure Mode and Effects Analysis (FMEA), FRACAS, Weibull Life Data Analysis, Accelerated Life Testing, Fault Tree Analysis (FTA) and Reliability Block Diagrams (RBD). Broadly applied across a range of industries, ReliaSoft offers the tools you need to ensure the safety, reliability and maintainability of your products and design.

What is ReliaSoft?

Solutions

FMEA / FMECA

Methodologies designed to identify potential failure modes for a product or process before the problems occur.

Failure Mode and Effect Analysis (FMEA) and Failure Modes, Effects and Criticality Analysis (FMECA) are methodologies designed to identify potential failure modes for a product or process before the problems occur, to assess the risk associated with those failure modes and to identify and carry out measures to address the most serious concerns.

Our Reliability Engineers have extensive experience of hosting FMEA and FMECA workshops in the Design, Process or Functional context. The workshops are performed to Industry specified requirements either as stand-alone activities or pre-cursors to RCM or Fault Tree activities.

Life Data Analysis / Accelerated Life Testing

Estimate life characteristics of a product such as reliability or probability of failure at a specific time.

Due to the long life-times of today’s products it can be difficult for an engineer to analyse the time-to-failure data obtained under normal operating conditions. However, Life Data Analysis (Weibull Analysis) enables you to predict the life of a product by fitting a statistical distribution to life data from a representative sample of units. This data set can then be used to estimate important life characteristics of the product such as reliability or probability of failure at a specific time, the mean life and the failure rate

In typical life data analysis, the practitioner analyzes life data from a sampling of units operated under normal conditions. This analysis allows the practitioner to quantify the life characteristics of the product and make general predictions about all of the products in the population. For a variety of reasons, engineers may wish to obtain reliability results for their products more quickly than they can with data obtained under normal operating conditions. As an alternative, these engineers may use quantitative accelerated life tests to capture life data under accelerated stress conditions that will cause the products to fail more quickly without introducing unrealistic failure mechanisms.

Our Reliability team supports clients through a number of Life Data Analysis and Accelerated Life Testing activities including Warranty Analysis, advice and recommendations on what data to be capturing to enable Life Data Analysis, Determining product reliability, product mean life or failure rate to support System Reliability Modelling. Our engineers support the development of Product Test planning, the determination of the number of samples to be tested and the level to which stressor levels are to be applied.

System Reliability Modelling

Improve or optimise overall system reliability, maintainability and/or availability using logic diagrams.

A system is a collection of subsystems, assemblies and/or components arranged in a specific design in order to achieve desired functions with acceptable performance and reliability. The types of components, their quantities, their qualities and the manner in which they are arranged within the system have a direct effect on the system’s reliability. Therefore, in addition to the reliability of the components, the relationship between these components is also considered and decisions as to the choice of components can be made to improve or optimize the overall system reliability, maintainability and/or availability. This reliability relationship is usually expressed using logic diagrams, such as reliability block diagrams (RBDs) and/or fault trees.

Supporting both product design and asset management functions, our Engineers develop and analyse system Reliability Block Diagrams and Fault Trees, usually as part of a Reliability project. These models can be made-up from a variety of sources of data from standards-based libraries, to real-world test/field data or from Supplier’s product technical specification data.

Using exact computations or discrete event simulation, our Engineers use ReliaSoft’s BlockSim software to undertake a wide variety of analyses for both repairable and non-repairable systems. This includes reliability analysis, reliability optimization, and sensitivity studies, exploring the effect of redundancy on improved reliability against increased cost.

Standards Based Prediction

Predict reliability for systems and components (mostly electronics) based on failure rate estimates.

Standards based reliability prediction is a methodology for predicting reliability for systems and components (mostly electronics) based on failure rate estimates published by globally recognized military or commercial standards. Standards based reliability prediction is especially useful in the initial stages of development when hard failure data is not yet available or when manufacturers are obliged contractually by their customers to use published standards for their reliability predictions.

Using ReliaSoft’s Lambda Predict software, our engineers can predict the reliability of your system to several standards including: MIL 217, FIDES, Bellcore/Telcordia; Siemens SN29500 and NSWC. Results are often subsequently used in System Reliability Models where test or manufacturer’s data is unavailable

Reliability Growth Analysis

Apply reliability growth models to analyze data from both developmental testing and fielded repairable systems.

ReliaSoft RGA allows you to apply reliability growth models to analyse data from both developmental testing and fielded repairable systems. In the development stage, the software allows you to quantify and track the system’s reliability growth across multiple test phases, while also providing advanced methods for reliability growth projections, planning and management. For systems operating in the field, RGA allows you to calculate optimum overhaul times and other results without the detailed data sets that normally would be required for repairable system analysis.

Working with Reliability and Test Engineers, our Reliability team can support the development of reliability goals, processes and test plans, thereby providing confidence in reliability growth projections and calculating optimum overhaul times for repairable systems.

FRACAS / DRACAS

Report failures and/or defects and track their corrective actions

Failure Reporting Analysis and Corrective Action System (FRACAS) and Defect Report Analysis and Corrective Action System (DRACAS) are commonly used terms for a system that is used to report failures and/or defects and track their corrective actions. Other commonly used names include DRACAS (Data Reporting Analysis and Corrective Action System), DCACAS (Data Collection Analysis and Corrective Action System) and CAPA software (Corrective And Preventive Action software).

For every installation of ReliaSoft’s XFRACAS software for FRACAS or DRACAS applications, our Reliability team works closely with our Clients to help configure and implement the software into the Client’s FRACAS/DRACAS processes. Our team can help develop the process if one isn’t already in place.

A key aspect of our work is the mass import of data into the XFRACAS system from external sources using a number of Data Analytics methods and the management of data that can interact with other Client systems.

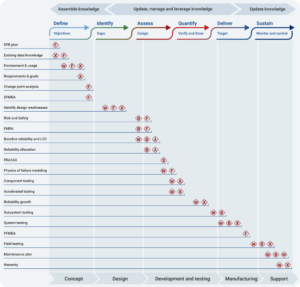

Industry-leading software to support DfR

Design for Reliability (DFR) can be described as a systematic, streamlined, concurrent engineering programme that supports product and process design (typically from early in the concept stage all the way through to product obsolescence) to ensure that customer expectations for reliability are fully met throughout the life of the product with low overall life-cycle costs. It relies on an array of reliability engineering tools along with a proper understanding of when and how to use these tools throughout the design cycle.

The DFR process encompasses a variety of techniques and practices, describing the overall order of deployment that an organisation needs to follow in order to design reliability into its products. This process is supported by ReliaSoft software, comprising tools that integrate for storing and transferring data between applications through a centralised database.

Benefits for Design for Reliability

-

Significantly reduce test time required to obtain reliability metrics for a product, which can result in faster time-to-market, lower product development costs and improved designs.

-

Design accelerated tests that will be the most effective to achieve desired objectives.

-

Predict performance during the useful life (or warranty) period.

-

Compare suppliers or designs based on reliability.

-

Demonstrate that an item meets a specified reliability.

-

Proactively consider potential failures, prioritize issues based on risk and then initiate improvements early in development when modifications tend to have the greatest impact for the lowest cost.

-

Address data capture and management deficiencies to provide timely and accurate product reliability, quality and safety data.

-

Contribute to design improvements, faster product release, better service and enhanced customer satisfaction.

-

Provide a closed-loop system for managing corrective actions.

-

Generate financial rewards through better product design, enhanced control of product warranties and more efficient customer support.

Reliability Management

ReliaSoft tools can help manage your reliability activities and overall strategies.

Our products include a comprehensive range of applications, such as ReliaSoft ReliaSoft XFMEA for FMEA and related analysis, ReliaSoft RCM++ for reliability centered maintenance, ReliaSoft XFRACAS for web-based failure reporting analysis and ReliaSoft SEP for KPI metrics, reports and project management. Modules for Risk Based Inspection analysis and MSG-3 maintenance program creation are also included.

Benefits for Asset Performance Management

-

Use simulation to obtain estimated performance metrics that can facilitate decision-making in a variety of areas, such as scheduling planned maintenance, planning for spares, identifying bottlenecks in production throughput and estimating life cycle costs.

-

Use Reliability Centered Maintenance (RCM) techniques to develop scheduled maintenance plans that will provide an acceptable level of functionality, with an acceptable level of risk, in an efficient and cost-effective manner.

-

Rank assets using a customizable qualitative risk discovery rating system and then use a quantitative analysis based on industry standards to predict risk for important assets.

-

Address data capture and management deficiencies to provide timely and accurate product reliability, quality and safety data.

-

Calculate optimum overhaul times and other results for fielded repairable systems.

-

Provide a closed-loop system for managing corrective actions.

ReliaSoft XFRACAS as a Base Solution for Asset Performance Management

ReliaSoft’s asset performance management solution helps collect, cleanse and analyze your CMMS (SAP, Maximo, etc.) or historian data in order to:

- Identify the bad actors of the current structure

- Estimate current fleet / equipment / item risk

- Estimate optimum replacement interval

- Update RCM and Maintenance Plans

- Calculate other reliability KPIs

ReliaSoft Product Suites

ReliaSoft software product suites are competitively priced to offer significant savings over purchasing the same products individually.

The suites are licensed as a single product. For a named user license, all applications must be activated by the same person. For a floating (multi-user) license, a seat for the entire suite will be taken when a user opens one or more of the applications in the suite.

ReliaSoft Master Suite

The ReliaSoft Master Suite includes the most powerful versions for the most commonly used applications.

Weibull++ – Reliability life data analysis

Lambda Predict – Standard based reliability predictions

XFMEA – FMEA and related analyses

BlockSim – RBDs, fault trees and Markov diagrams

RCM++ – Reliability centered maintenance

DRR Suite

The Design for Reliability (DFR) suite is configured primarily for users focused on product design and development.

Weibull++ – Reliability life data analysis

XFMEA – FMEA and related analyses

BlockSim – RBDs, fault trees and Markov diagrams

RAM Suite

The Reliability, Availability and Maintainability (RAM) suite is configured primarily for users focused on equipment operation and maintenance.

Introducing ReliaSoft 2023

We are pleased to announce the availability of ReliaSoft 2023, offering important software usability improvements and new methods designed to make your reliability analyses more effective, improve your productivity with streamlined user experience.

ReliaSoft 2023 is designed to make your reliability analyses more effective and improve your productivity with streamlined user experience. Enhancements include:

Fault Tree Analysis

Building on the Binary Decision Diagram introduced in 2022, ReliaSoft BlockSim 2023 now allows you to take your Fault Tree Analysis even further by utilizing the Binary Decision Diagram Approximation Method. This new analytical calculation method allows for even larger Fault Tree Analyses, with the power to evaluate FTAs that contain hundreds of thousands of events and gates

FMEA-MSR – AIAG/VDA 1st Ed and J1739 (2021)

In ReliaSoft 2023, we have added support for the Failure Modes and Effects Analysis – Monitoring and System Response (FMEA-MSR) analysis to both the AIAG/VDA 1st Ed and SAE J1739 (2021) FMEA profiles available in ReliaSoft XFMEA/RCM++ software. This new update will allow customers to follow the entirety of both FMEA handbooks cover to cover. Design teams following this methodology can now fully document and take credit for their monitored control systems in their design.

BlockSim API

Beginning in Version 2023, ReliaSoft users who utilize the Prenscia Access License will have access to the BlockSim simulation API methods. These calls will allow users to trigger simulations of Reliability Block Diagrams and obtain results from those simulations from outside of the BlockSim user interface. Combining this with the other ReliaSoft APIs will enable users to utilize the full power of BlockSim’s availability and maintainability toolset, with the flexibility of modifying and updating existing reliability policies and assumptions from a programmatic interface.

Resources

Availability, Reliability & Maintainability for Defence Standards Webinar Series | Session 1: Implementing Reliability Software to support the Defence Industry

Read more

Availability, Reliability & Maintainability for Defence Standards Webinar Series | Session 3: Beyond DEF-STAN Requirements

Read more

Availability, Reliability & Maintainability for Defence Standards Webinar Series | Session 2: Conforming to DEF-STAN ARM Requirements

Read more

Webinar: ReliaSoft XFRACAS as a Base Solution for Asset Performance Management

Read more

Webinar: Design for Reliability – How to Set Reliability Targets Using ReliaSoft Software

Read more

Webinar: Design for Reliability – Reliability Risk Identification and Mitigation Using ReliaSoft XFMEA

Read more

Webinar: Using FMEA to Mitigate Risk and Warranty Exposure of Electric Vehicle Batteries

Read more

Testimonial Video: ReliaSoft Success Story Lowering the Failure Rates of Complex Networks

Read more

Testimonial Video: ReliaSoft Success Story Effectively Presenting Accelerated Life Test Results

Read more

Testimonial Video: ReliaSoft Success Story Integrating FMEA Activities Across the Organisation

Read more

Testimonial Video: ReliaSoft Success Story Analysing Failure Data to Reduce Test Times

Read more

Webinar: ReliaSoft Weibull++: Using Warranty Data Analysis for Making Business Decisions

Read more

How Can ReliaSoft Help Your Reliability Strategies?

Our combined software, training and consulting solutions enable you to develop your reliability engineering capabilities within your business efficiently and effectively, with expert support and mentoring from our experienced technical services team.

For more information or to arrange an informal, no-obligation discussion on your requirements, please complete the form opposite or contact us using the details below.

The problem was understood and resolved straight away. Good work, thank you.

Edwards Ltd (Burgess Hill)

Your [ReliaSoft] software is extremely user friendly and easy to use. It enables us to make fact based decisions.

Raytheon

I was delighted to find new and efficient ways to use the software, I’ve already used for 6 months. It was definitely a good learning experience.

Quanta Fluid Solutions

I currently use Weibull++, BlockSim & Lambda Predict and am very pleased with the software. I have been an every day user of alternative suppliers’ reliability software and found ReliaSoft to be the most comprehensive and user friendly.

Seagate Systems UK

... certainly impressed with ReliaSoft products, having had chance to use Weibull++ for themselves, and shared in the analysis of their paper-clip exercise on ALTA PRO. BlockSim just did everything that they would expect.

University of Warwick

ReliaSoft is indeed an excellent software, I would like to be an ambassador and recommend it to more people …..I am also very, very satisfied with all your services

Offshore Renewable Energy Catapult

Great to be shown the full applications in the software [Lambda Predict] and how they overlap.

Camcon Technology

The [ReliaSoft] Weibull++ software is a powerful, practical and easy to use package for life data analysis. Its graphical user interface enables new users to master this tool in a relatively short period of time. I recommend this tool in my organisation.

Chevron Texaco

I currently use Weibull++, BlockSim & Lambda Predict and am very pleased with the software. I have been an every day user of alternative suppliers’ reliability software and found ReliaSoft to be the most comprehensive and user friendly.

Xyratex Storage Systems

Very useful [ReliaSoft] tools to conduct reliability analysis.

Dyson

Outstanding software. I’ve been trying to force reliability methods into other software. It’s a relief to use a system specifically designed for reliability.

Cummins Turbo Technology