Rapid Design and Optimisation of Flow and Heat Transfer Systems

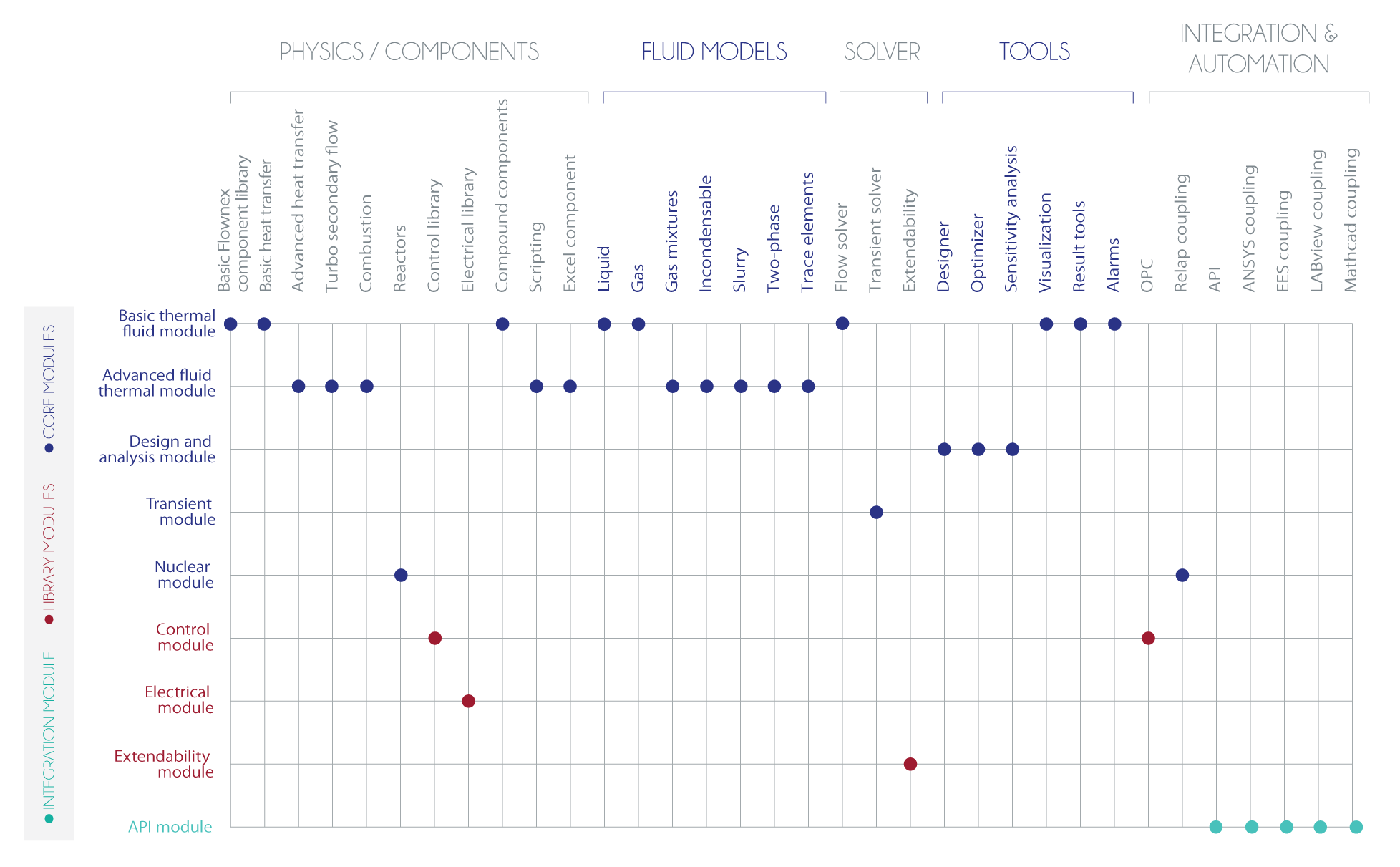

Developed by M-Tech Industrial, Flownex provides an ideal systems-based simulation tool for virtually all fluids-based processes.

It can model any combination of liquid, gas, two phase, slurry and mixture flows in both steady state and dynamic conditions, coupled with a comprehensive library of components including pumps, turbines, valves, compressors and heat exchangers.

I was very impressed with the knowledge and tools available to us through Wilde and the accuracy of their first model predictions compared to my test results. This has already become a seminal piece of work that will underpin a significant future product development.

Edbro