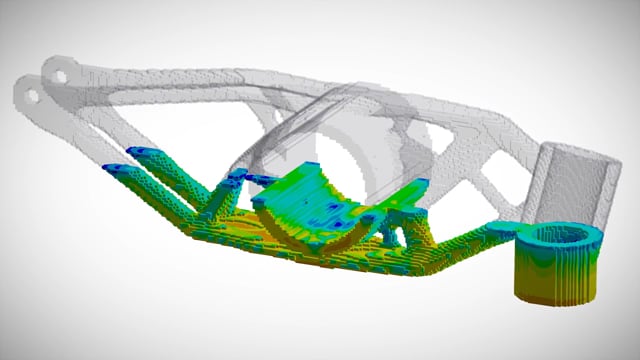

Take Control of Your Entire Additive Manufacturing and 3D Printing Processes

Ansys’ best-in-class solution for additive manufacturing enables simulation at every step in your AM process. It will help you optimise material configurations and machine and parts setup before you begin to print. As a result, you’ll greatly reduce — and potentially eliminate — the physical process of trial-and- error testing.