Multiphysics Process Modelling

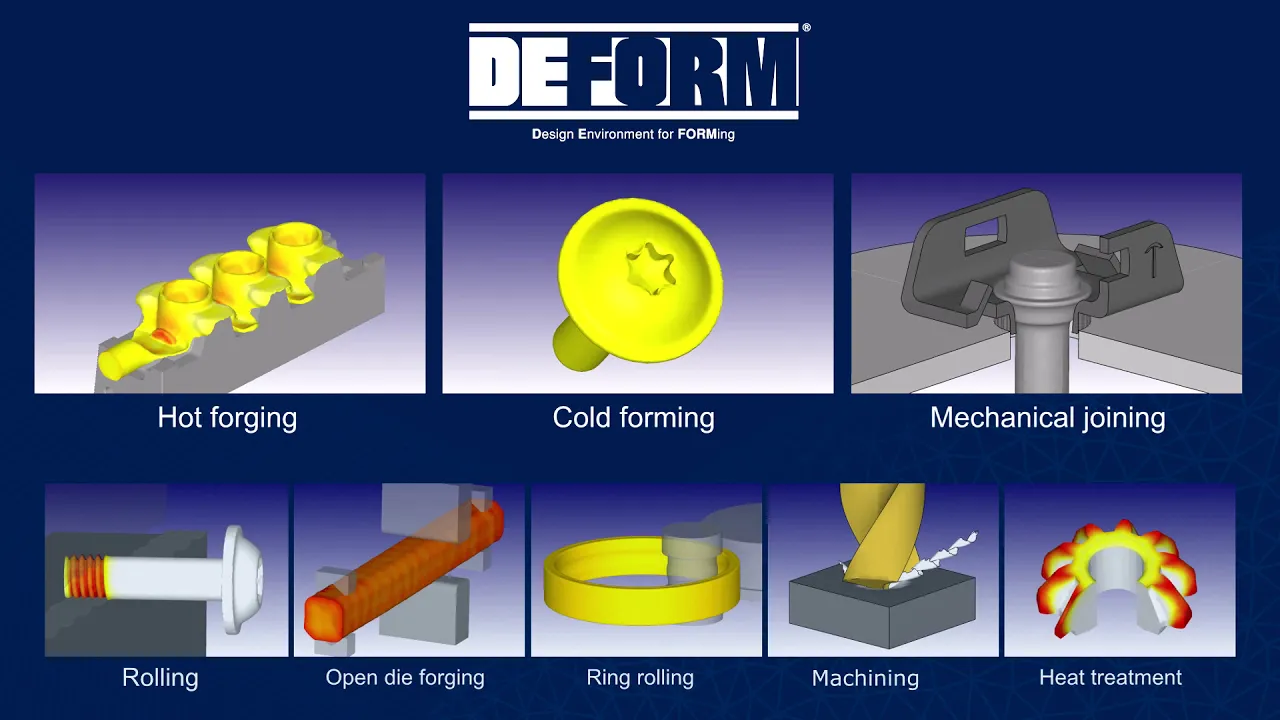

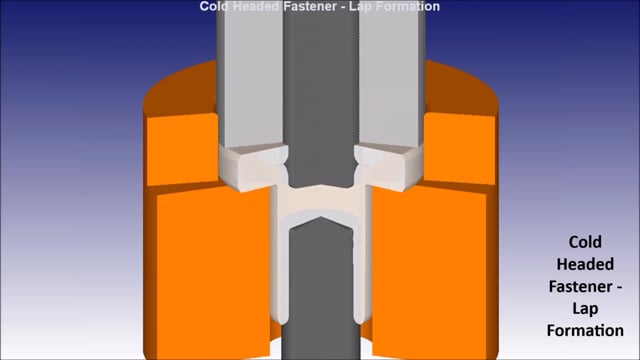

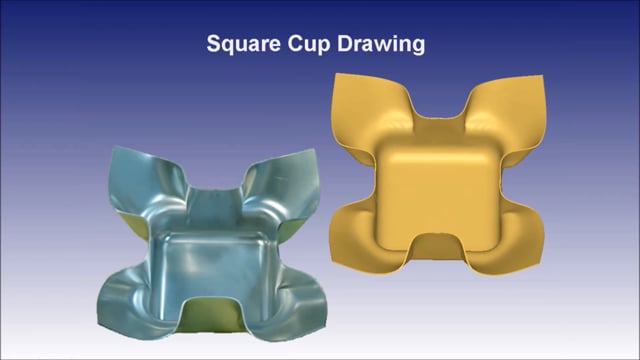

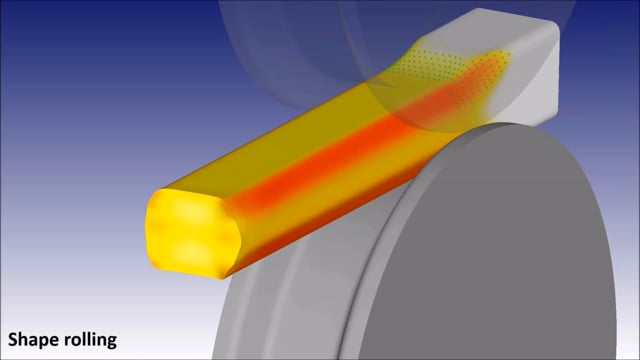

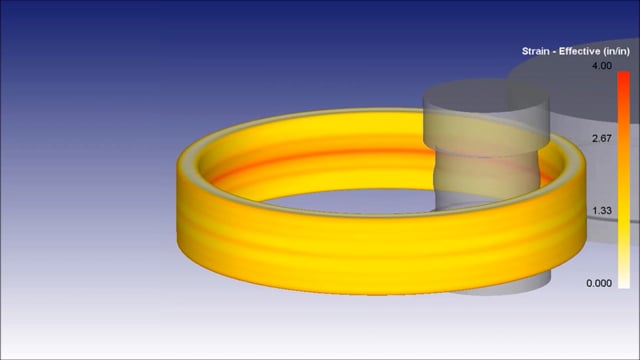

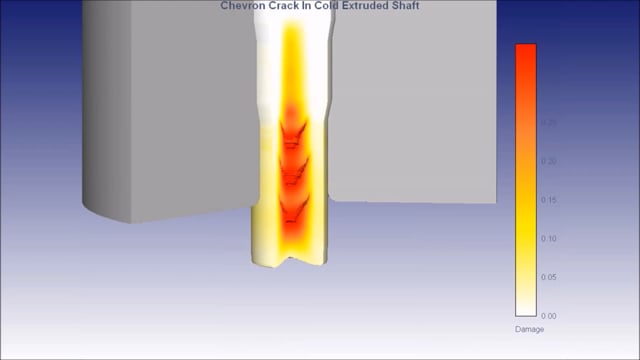

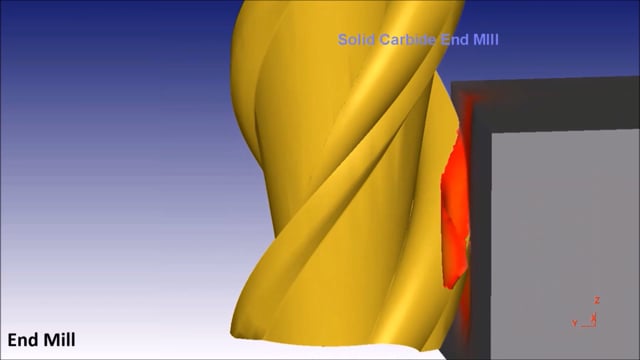

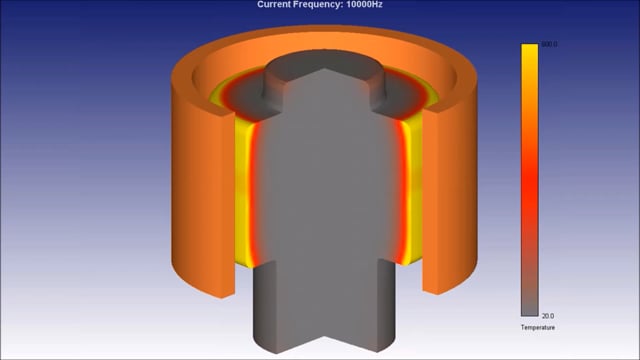

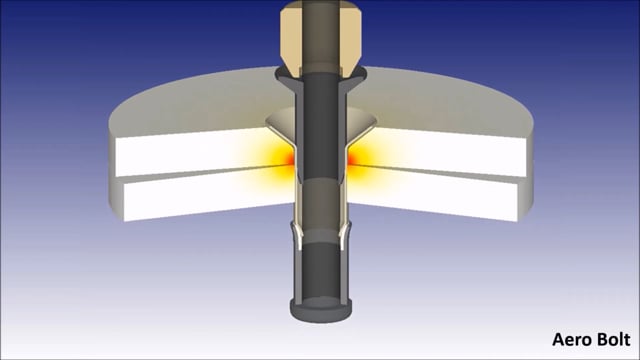

DEFORM is specifically designed to simulate cold, warm and hot manufacturing operations for preform optimisation, tooling and product development, process troubleshooting and die stress analysis. Typical applications include forming, heat treatment and machining.

Developed by SFTC, automatic remeshing capabilities and robust non-linear solvers enable extremely large deformation material flow and coupled thermal behaviour to be simulated efficiently and accurately – often beyond the capabilities of general purpose FEA codes.

DEFORM is used by major aerospace, automotive, industrial equipment, bio-medical and nuclear companies, together with their supply chains and leading research institutions.

We are the dedicated channel partner for DEFORM in the UK and Northern Europe.

...the support provided by Wilde Analysis has always been exceptional.

University of Sheffield (AMRC)

Excellent support, very rapid and pointed me in the right direction to solve my simulations.

STANLEY Engineered Fastening (Letchworth Garden City)

Using DEFORM, we estimate that we have reduced the number of samples required by around 50%... The confidence acquired in material volume and raw stock size has consented bulk material purchase giving a great reduction on initial lead times. DEFORM 3D is now an integrated part of Cerro EMS’ die design procedure.

Cerro EMS Limited

Manufacturing research is crucial for advancements in quality, production and in reducing the costs associated with the manufacture of parts. Finite element analysis is a powerful tool used to assist this process. DEFORM has been used as a tool to more effectively understand the machining process.

University of Sheffield (AMRC)

....our Design Engineers have all been trained by, and worked with, Wilde Analysis to exploit DEFORM more and more....Wilde Analysis has been there over the years to help us make those key steps forward in our FEA capability.

Stanley Engineering Fastening

Through the years, STANLEY Engineering Fastening’s engineers have experienced many benefits in using DEFORM within product and manufacturing design, rather than simply relying on conventional methods involving trial and error.

Stanley Engineering Fastening

DEFORM has impressive capabilities and applications; the course is extremely useful!….Within three days you will have the ability to work on real applications.

Manufacturing Technology Centre

…especially appreciate the time to look at my specific examples & advised me with the right solutions.

University of Hull

New and intermediate level users will find this extremely useful to cope with more advanced models and the current expectations in the field of FE modelling of manufacturing operations.

University of Strathclyde (AFRC)

A highly informative meeting, showcasing the new developments in software capability... It was the first UGM for me and I really enjoyed it. It is good to see how much support you can get from SFTC... This meeting provided me with a useful update on the new features in DEFORM.

University of Birmingham (PRISM2)

The level of support was excellent. My query was dealt with in a speedy and efficient manner with easy to follow instructions which resolved the issue. Thank you.

Timet UK

The [technical support] team is very pro-actively engaged in any problem(s) we may have related to hardware or software. Extremely helpful in any way and any level of support.

Stanley Engineered Fastening

The course was extremely informative & an ideal introduction to the DEFORM Machining Simulation. … Great people, well planned course, informative materials, excellent refreshment, so thank you very much.

University of Northumbria