We recommend the appropriate technology to suit your requirements, enabling plastic product quality to be validated before investing in expensive tooling.

Software and Consulting

We provide flexible and fast-response injection molding simulation consulting services to clients without the time, skills or resources in-house – from single day plastic design assessment to long-term product and mold development projects. Our services are typically employed to screen for and detect voids & sink marks, gas traps and weld lines with the objective to optimize fill patterns.

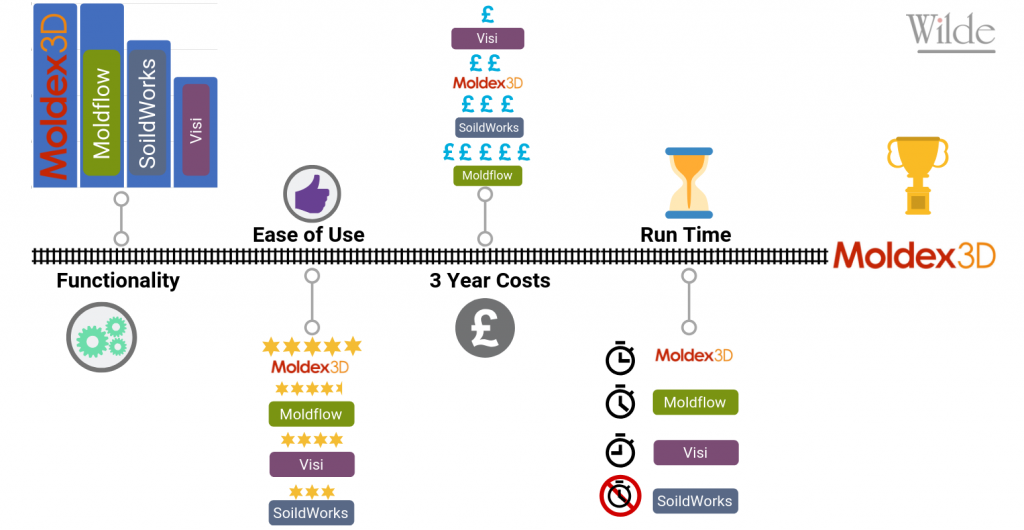

As a Moldex3D value-added reseller, we supply the automotive, medical, consumer, packaging and other industries involved in designing and/or manufacturing plastic products with leading simulation software. In addition, we can model plastic blow molding and extrusion manufacturing operations through complementary ANSYS Polyflow simulation tools.

We are internationally recognised through our Moldex3D Expert Certification.

Materials Expertise

We have experience in a diverse range of polymers from commodity plastics such as PP and ABS through to fibre-reinforced Polyamides, PEEK and PPS. We can simulate over 8000 grades subjected to the following processes:

- Thermoplastics Injection Molding

- Thermoplastics Injection Compression Molding and Overmolding

- Gas-assisted Injection Molding

- Reactive Molding

- Reactive Compression Molding

- Reactive Injection-Compression Molding

- Microchip and Underfill Encapsulation

- Insert molding/2K – Multi-Component Molding (MCM)

- Injection compression Molding

- Resin Transfer Molding

- Foam Injection Molding

- Powder Injection Molding

- IC Packaging

- PU Chemical Foaming Molding

- Conformal Cooling

- Investment Casting

Design for Manufacture

Together with our Structural Analysis capabilities, we help ensure that any plastic component is Designed for Manufacture, balancing product performance in terms of strength, rigidity and fatigue life with minimum cost production. For fibre-reinforced plastics, our software can incorporate inhomogneous and directional material properties developed during the molding process within design simulation studies of parts.

(Image courtesy: Mergon)

Example Projects

-

Two-Shot & Insert Overmolding

Assessment of subsea connectors, electronic devices, automotive sensors and interior trim

-

Core Deflection

Analysis of mould tool robustness & process repeatability in medical, automotive & industrial equipment sectors

-

Gate Position Evaluation

Optimization of hot & cold feed systems, including large components with sequential valve gated systems

-

Cooling Optimisation

Minimisation of cycle times and costs by eliminating hot spots in mold tools, including conformal cooling

-

Fibre Orientation Analysis

Prediction of mechanical properties of parts manufactured from high-performance engineering polymers

-

Shrinkage & Warpage Prediction

Simulation and reduction of shrinkage/warpage/distortion across all industries

Resources

How Can We Help?

For more information or to arrange an informal, no-obligation discussion on your requirements, please complete the form opposite or contact us using the details below.

From an initial phone call we can often give you an idea of price and time scales.

With subsequent details, we can then send you some solution ideas, scopes of work and a formal quotation.

The course was well structured and professionally conducted.

Owen Mumford

Excellent course…..A fantastic refresher of key aspects of design for moulding, plus a gentle yet thorough introduction to the capabilities of the software.

Depuy Synthes

The consultancy project enabled us to spot errors that would have cost much more than the sum of the analysis itself. It enabled us to see things before we committed to them which is very beneficial, especially in terms of the high financial investment involved in the design of the larger components. It made sense to us to analyse these high value components, as the cost of modifying the tooling is so high.

Dudley Industries

For us, the advantage of using Wilde’s consultancy services is that we can give our client confidence in the results that we present to them.

Precision Moulds & Tools Services

The course is well trained and I leave the course with lots more knowledge learned to take back with me in my new role... I had never used Moldflow before and will leave the classroom confident that I will now be able to perform Moldflow analysis with the aim of progressing to the next level very soon.

Owen Mumford

An essential course for the injection molding trade. Well laid out and very easy to follow. Definitely recommended for injection molding/anyone working with polymers.

Denroy Plastics

Pace plc

... Our improved in-house capability has speeded up our development schedules & helps us to progress our designs & testing much faster, with lead time reductions of around 80%...We see Wilde as a key partner in the development of our skills & software capability.

Nifco

The guys at Wilde Analysis are very knowledgeable and passionate about what they do. I advise anyone needing analysis/training to make contact with Wilde. I thoroughly enjoyed my 3 days training and will be completing another course in the near future.

SET Europe