When clients have not had the resources to perform simulations themselves, we have worked in partnership to solve their manufacturing issues and create more robust, cost-effective processes.;

Manufacturing simulation helps engineers gain an in-depth understanding of how their process performs and the resulting metallurgical properties following manufacture. By simulating their metals-based manufacturing processes, our clients have:

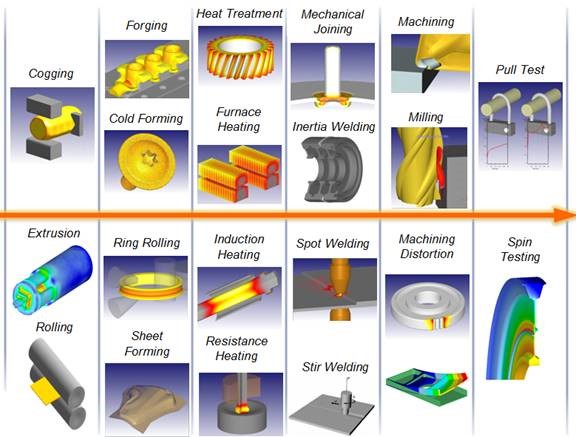

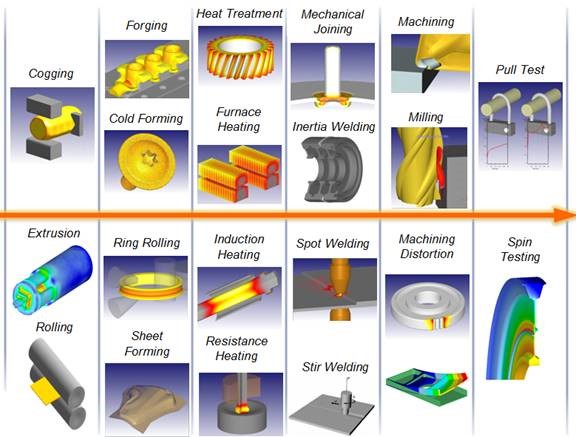

As Northern European channel partner for DEFORM and UK & Ireland reseller for Ansys Forming, we have provide software and consulting solutions since 1997 that can address challenges and design issues with most metals-based manufacturing operations.

Many have been using DEFORM for between 10-20 years with our support and training, due to its accuracy, ease-of-use and flexibility to simulate complex large deformation, themo-mechanical phenomena associated with manufacturing metal parts – from initial material preparation and furnance heating to final forming, machining and heat treatment.

For forming processes where the metal is exhibiting predominantly ‘fluid’ rather than ‘solid’ behaviour, we also call upon our in-house fluid dynamics specialists and Ansys CFD software.

When clients have not had the resources to perform simulations themselves, we have worked in partnership to solve their manufacturing issues and create more robust, cost-effective processes.;

For more information or to arrange an informal, no-obligation discussion on your requirements, please complete the form opposite or contact us using the details below.

From an initial phone call we can often give you an idea of price and time scales.

With subsequent details, we can then send you some solution ideas, scopes of work and a formal quotation.

...the support provided by Wilde Analysis has always been exceptional.

University of Sheffield (AMRC)

Excellent support, very rapid and pointed me in the right direction to solve my simulations.

STANLEY Engineered Fastening (Letchworth Garden City)

Manufacturing research is crucial for advancements in quality, production and in reducing the costs associated with the manufacture of parts. Finite element analysis is a powerful tool used to assist this process. DEFORM has been used as a tool to more effectively understand the machining process.

University of Sheffield (AMRC)

....our Design Engineers have all been trained by, and worked with, Wilde Analysis to exploit DEFORM more and more....Wilde Analysis has been there over the years to help us make those key steps forward in our FEA capability.

Stanley Engineering Fastening

Through the years, STANLEY Engineering Fastening’s engineers have experienced many benefits in using DEFORM within product and manufacturing design, rather than simply relying on conventional methods involving trial and error.

Stanley Engineering Fastening

DEFORM has impressive capabilities and applications; the course is extremely useful!….Within three days you will have the ability to work on real applications.

Manufacturing Technology Centre

New and intermediate level users will find this extremely useful to cope with more advanced models and the current expectations in the field of FE modelling of manufacturing operations.

University of Strathclyde (AFRC)

A highly informative meeting, showcasing the new developments in software capability... It was the first UGM for me and I really enjoyed it. It is good to see how much support you can get from SFTC... This meeting provided me with a useful update on the new features in DEFORM.

University of Birmingham (PRISM2)

The level of support was excellent. My query was dealt with in a speedy and efficient manner with easy to follow instructions which resolved the issue. Thank you.

Timet UK

The [technical support] team is very pro-actively engaged in any problem(s) we may have related to hardware or software. Extremely helpful in any way and any level of support.

Stanley Engineered Fastening

Very informative and professional course.

Timet UK

The course was extremely informative & an ideal introduction to the DEFORM Machining Simulation. … Great people, well planned course, informative materials, excellent refreshment, so thank you very much.

University of Northumbria