Latest Advances in Flat Fibre Filled Injection Moulding Simulation | Moldex3D Blog

August 7th, 2019

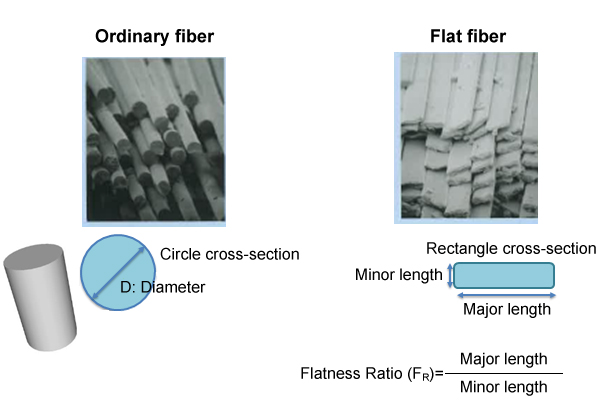

Fibre-reinforced thermoplastic (FRT) composites have been widely used in the automotive industry to enhance mechanical properties and reduce warpage deformation. Fibres are usually processed into the form of rods with round cross-sectional shapes. Flat fibres have been recently developed by Nitto Boseki (NITTOBO) Co., Ltd. in Japan [1], which is a Tokyo-based company specializing in textile and fibreglass products. Basically, the cross-sectional shape of a flat fibre is close to a rectangle. To calculate the flatness ratio (FR), divide the length to the width (Fig. 1).

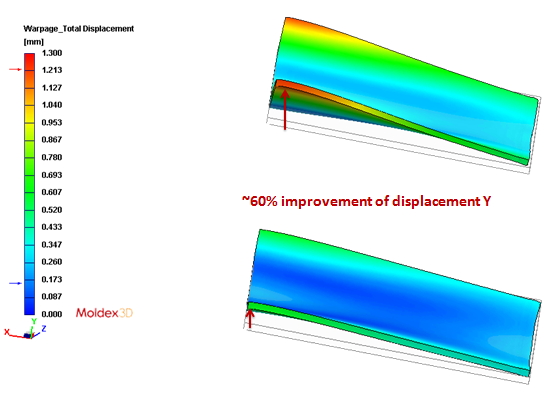

The patent and report published by Nitto Boseki (NITTOBO) indicated that the warpage displacement of a flat-fibre filled thermoplastic plate (width = 7µm , length = 28µm , FR = 4) has been reduced by 80% comparing to ordinary fibres.

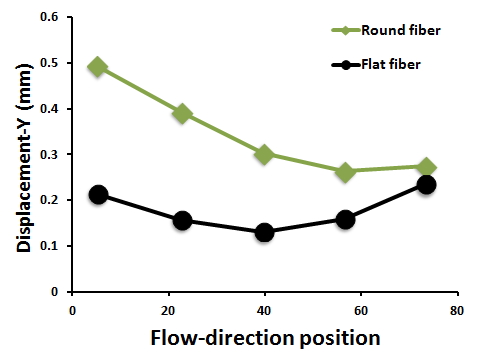

However, very little research has focused on flat fibres, and the technology was not there to simulate and validate flat fibres. To address this issue, the latest version of Moldex3D plastics moulding simulation software, R17, has developed new capabilities to predict and validate flat fibre injection moulded parts. This can help designers and engineers achieve better mechanical properties and improved dimensional stability. We will compare two warpage displacement results between round fibres and flat fibres (50wt% glass fibre/PP composites) in the following case. For the round fiber, the fibre length LF is 0.3 mm, the fibre diameter is 15µm , and the aspect ratio is 20. For the flat fibre, the fibre length LF is 0.5 mm, the flat ratio FR = 4, the minor length Lmin= 7µm , and the major length Lmax = 28µm .

Fig. 2 shows that flat fibres can effectively reduce the Y-displacement by 60%. Moreover, Fig. 3 indicates that the Y-direction (the part thickness direction) displacement along the X-axis flow length for flat fibre is obviously smaller than round fibre with an improving percentage of about 60%. Moldex3D Fiber analysis results have demonstrated that flat fibers can provide better dimensional stability compared with round fibers. It is expected that the utilisation of flat fibres in various applications will continue to grow.

For more information about the Moldex3D product range, please click here >>

Talk to one of our account managers for how Moldex3D can benefit you, call now on 0161 474 6886.