Design, Refine and Manufacture Advanced Fastening Systems - Virtually

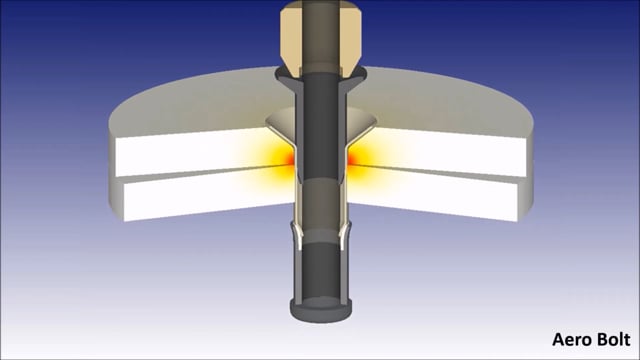

Fastener and precision cold forming manufacturers are using DEFORM to simulate mechanical joining processes, such as riveting, bolting, and clinching, to accelerate product development and avoid the cost and time of physical testing. This includes the modelling of annealing operations designed to locally soften material and influence its deformation behaviour. DEFORM can predict the shape of each component, installation load, torque, joint strength and tool stress.

Furthermore, DEFORM's renowned process modelling capabilities are also applied to the manufacture of fastener products, including cold and warm forming operations. Progression designs can be optimized through virtual prototyping to reduce number of stages, decrease forming load requirements, minimize die stresses and increase tool life.

...the support provided by Wilde Analysis has always been exceptional.

University of Sheffield (AMRC)

Excellent support, very rapid and pointed me in the right direction to solve my simulations.

STANLEY Engineered Fastening (Letchworth Garden City)

Manufacturing research is crucial for advancements in quality, production and in reducing the costs associated with the manufacture of parts. Finite element analysis is a powerful tool used to assist this process. DEFORM has been used as a tool to more effectively understand the machining process.

University of Sheffield (AMRC)

....our Design Engineers have all been trained by, and worked with, Wilde Analysis to exploit DEFORM more and more....Wilde Analysis has been there over the years to help us make those key steps forward in our FEA capability.

Stanley Engineering Fastening

Through the years, STANLEY Engineering Fastening’s engineers have experienced many benefits in using DEFORM within product and manufacturing design, rather than simply relying on conventional methods involving trial and error.

Stanley Engineering Fastening

DEFORM has impressive capabilities and applications; the course is extremely useful!….Within three days you will have the ability to work on real applications.

Manufacturing Technology Centre

New and intermediate level users will find this extremely useful to cope with more advanced models and the current expectations in the field of FE modelling of manufacturing operations.

University of Strathclyde (AFRC)

A highly informative meeting, showcasing the new developments in software capability... It was the first UGM for me and I really enjoyed it. It is good to see how much support you can get from SFTC... This meeting provided me with a useful update on the new features in DEFORM.

University of Birmingham (PRISM2)

The [technical support] team is very pro-actively engaged in any problem(s) we may have related to hardware or software. Extremely helpful in any way and any level of support.

Stanley Engineered Fastening